Manufacturing is a complex process where raw material is converted into finished products by use of the manual labor or by machinery especially on large scale. Now new means and ways are being adopted in manufacturing field with the innovative methods and approach.

There

is a great need for an ERP for manufacturing company as it has that

capabilities and features which can easily handle and manges

different aspects of the manufacturing. For Manufacturing industries,

the production of goods and materials is carried out in step by step

process. There are various departments

are

involved in manufacturing sector.

Manufacturing

has emerged as one of the high growth sectors in India. There is a

huge aspects of getting successful and organized in the field of

manufacturing. Manufacturing involves large number of heavy machines,

inventory system, raw materials, furnished materials and supply chain

management system and so on.

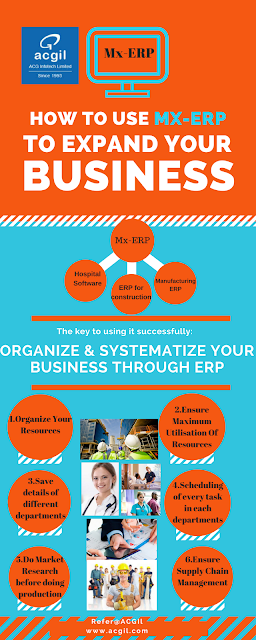

What

an ERP for manufacturers does? Actually, it makes the manufacturing

organized, systematic and precises as it accumulates and stores all the

informations regarding the production process under one system. There

are various ERP vendors in India to pick the best ERP one has to be

smart and excellent. Mx-ERP, designed and developed by the ACGIL,

India, one of the best competent and excellent ERP for all business.

What

an ERP for manufacturers does? Actually, it makes the manufacturing

organized, systematic and precises as it accumulates and stores all the

informations regarding the production process under one system. There

are various ERP vendors in India to pick the best ERP one has to be

smart and excellent. Mx-ERP, designed and developed by the ACGIL,

India, one of the best competent and excellent ERP for all business.

Benefits

of Mx-ERP:

1.Better

User-Friendly Environment:

It

offer easy and user-friendly environment friendly for interaction

between various components of the manufacturing.

2.Cost-Effective:

It

is cost effective as it offer various packages to provide ERP

packages.

3.Control

Manufacturing Resource:

It manages all the resources which can

control the manufacturing of different products and goods.

4.Fantastic

Material Management:

It ensures fantastic material management of all the materials involved in the process of manufacturing and production of the goods.

5.Streamline Different Processes:

As the product manufacturing increases, ero

software streamline all the business processes.

6.On-Time

and Flawless Delivery:

It ensures on-time and flawless delivery of finished products and goods.

7.Offer

Data Analysis Mechanisms:

It assists in carrying out the data analysis