Manufacturing

is a a very complex and wide field where different products are being

manufactured and produced. Manufacturing of any product requires

several aspects and to manage these a software is required. In line

with that a manufacturing ERP Software is employed to monitor

manufacturing and its various aspects and deliver the best results

which ensures profit for the business.

In

fact, a manufacturing ERP, is an integrated system which helps to run

the manufacturing business in a better way. The software system,

offers support for an entire range of industry processes and

operations including procurement, manufacturing, inventory

management, supply chain planning, sales & marketing, asset

maintenance,finance, human capital management , payroll and business

analytics.

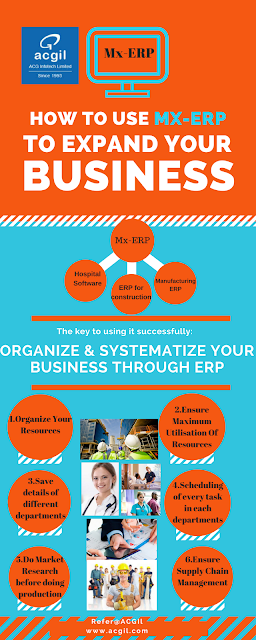

ERP

Manufacturing software is customizable and can be fit for any

manufacturing environment for small or mid-sized manufacturing

Industry. Out of several ERP available in the market, Mx-ERP

is the best ERP manufacturing software as it is easy to use and can

be implemented economically.

Benefits

of Manufacturing ERP(Mx-ERP)

1.Simple

to install, Low maintenance & built for the shop floor

environment:

Its

installation is simple,cost effective as well as maintenance cost is

also very less and it is built for shop floor environment.

2.It

assists in machine utilization, scrap & downtime reporting:

It

examine and create all the reports related to machine utilization and

ensures the best utilization of the every machine, management of

industrial scrap and downtime reporting in the production is also

done.

3.Identifying

the machine performance:

A

report based on the functioning and working of different machines is

made with all the details related to performance of machines and

their efficiencies is made.

4.Simplifies

shift reporting & inventory reconciliation:

It

simplifies reporting of productions in different shifts and inventory

reconciliation representing the reporting about the actual amount of

materials in inventory and the inventory records previously

available.

5.Managing

the entire production process:

It

manages all the production & their processing in the production

system.

6.View

overall enterprise or specific work center:

To

view the details of any specific work center, this software provide

the facility to view the details of any specific department and their

functions.

7.Follow

Jobs in real-time:

As

jobs are done and followed in a proper schedule through production

process